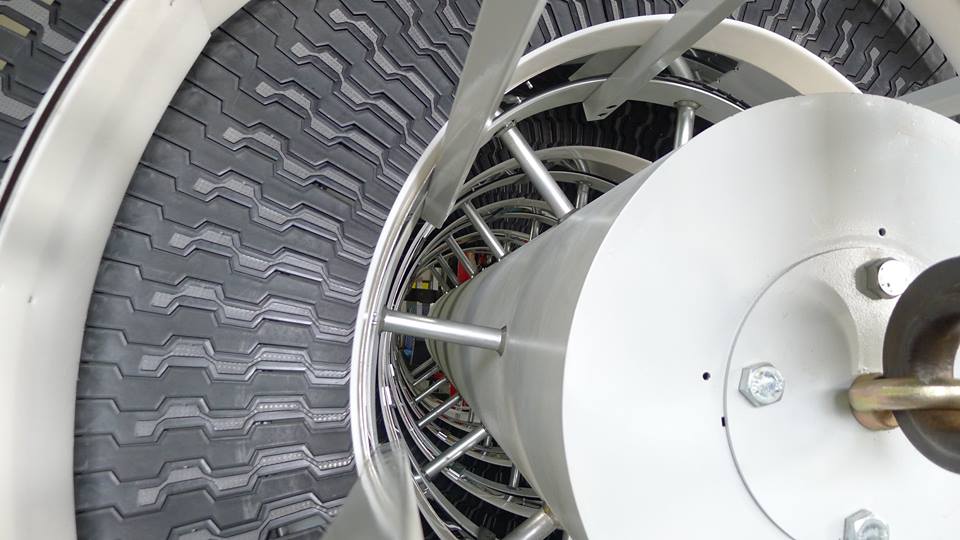

Spiral conveyor system is used to raise or lower materials to different levels of a facility during handling process.

It is the perfect solution of vertical conveying, and a good spiral conveyor design can nicely optimize the production capacity and greatly saves cost.

However, most of the users don’t know how to choose a suitable spiral conveyor for their production lines. Here is a beginner’s guide that may help you to have a a basic understanding about spiral conveyors.

Step 1: Choose the type of spiral conveyor

The right type of the spiral conveyor depends on the size of products and the function you expect the spiral conveyor to achieve.

For example:

- The products (cartons, bags, pouches, etc.) need to be conveyed one by one in single line → Unit Load Spiral Conveyor

- The products (bottles, cans etc.) need to be conveyed in single & continuous flow → Narrow Track Spiral Conveyor

- Two different sizes or kinds products need to be conveyed at the same time, or there is requirements to double the throughput → Dual Track Spiral Conveyor

- Multiple input or output in different levels/floors in a single conveyor → Multiple Inlet and Outlet Spiral Conveyor

- The products (print finishing, packed cheese/yogurt, etc.) need cooling during handling process → Cooling Spiral Conveyor

Step 2: Confirm the slat chain width

It depends on the size (length*width) and leading side of your product. At present 135 mm, 165 mm, 400 mm and 600 mm are our standard width, the other widths are customized.

Step 3: Choose the correct material of spiral conveyor

Mild steel painted material can meet most of the application requirement; Stainless steel material is the only option for applications which require high sanitation and anti-corrosion.

Step 4: Choose the suitable speed and if the speed should be adjustable

Speed of the conveyor mainly depends on your requirements of throughput, if adjustable speed is needed, it totally depends on your own application in factory.

Step 5: Choose the running direction of spiral conveyor, fixed or adjustable

Majority of the users don’t have demand for the directions of spiral conveyor, it always fixed to be upwards or downwards, however, very few of them needs the directions of spiral conveyor adjustable to achieve occasional change in running way, if so, you need to let the designer know this point in advance.

As an expert of spiral conveyor, NEXUS have rich experience both in design and manufacturer, so can be your reliable choice for your spiral conveyor design, click here to learn more about NEXUS spiral conveyor, and you can also contact us directly.